Interactivity and advanced control are the focus of arge.visor, the brand new software developed by argesystems®. Designed for a real-time and integrated robotic bending cell management.

arge.visor is the latest technology developed by argesystems®’ software engineers. It has been designed to grant a complete overview and to optimize the bending cell management. It marks a significant progress in the bending sheet metal field, in line with Industy 4.0 guidelines.

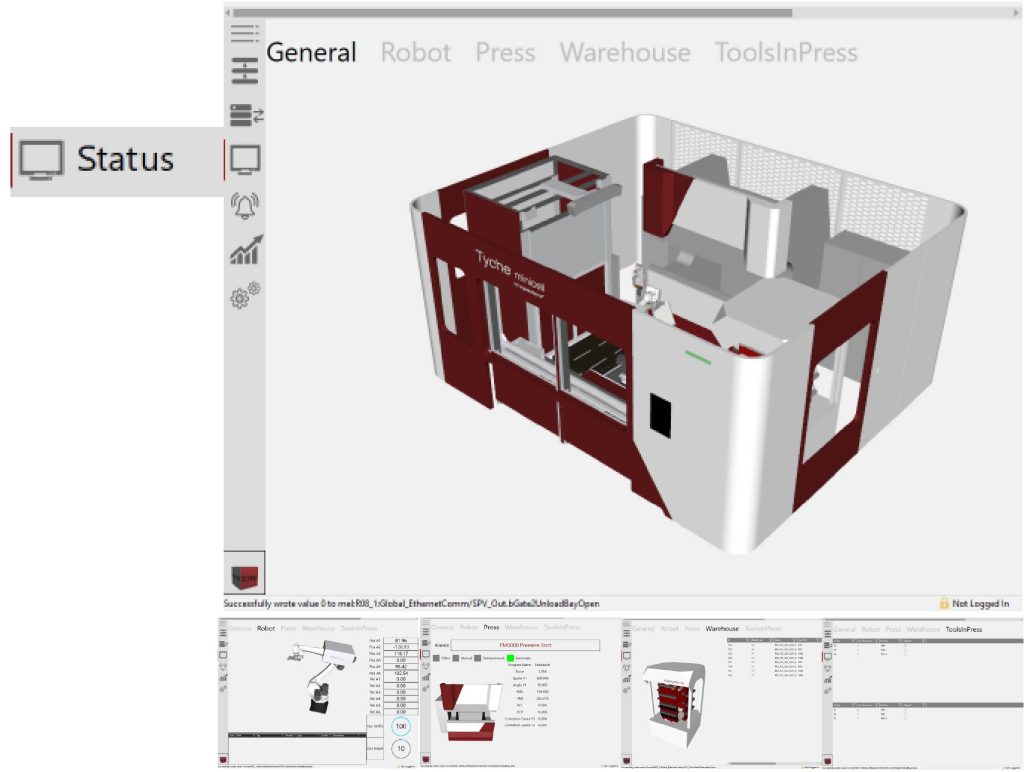

This software allows to control the bending cell from a 3D visualization on the on-board HMI. It has been designed for a smart and interactive representation of the bending process: the operator can manage and monitor every component inside the cell in real time, from the outside.

This integration makes the communication between the bending cell and the ERP systems possible, by creating a production schedule for the cell.

Its strength is the robotic cell interface.

A touch screen positioned outside – equipped with a smart inteface – enables a complete interaction without buttons; all the operations can be accomplished easily on the 3D model of the bending cell.

Visualization and action are perfectly matched, thanks to an interactive screen which allow the operator to open the cell doors, view electrical diagrams, work cycles, and alarms, and, finally, schedule maintenance.

How to use arge.visor?

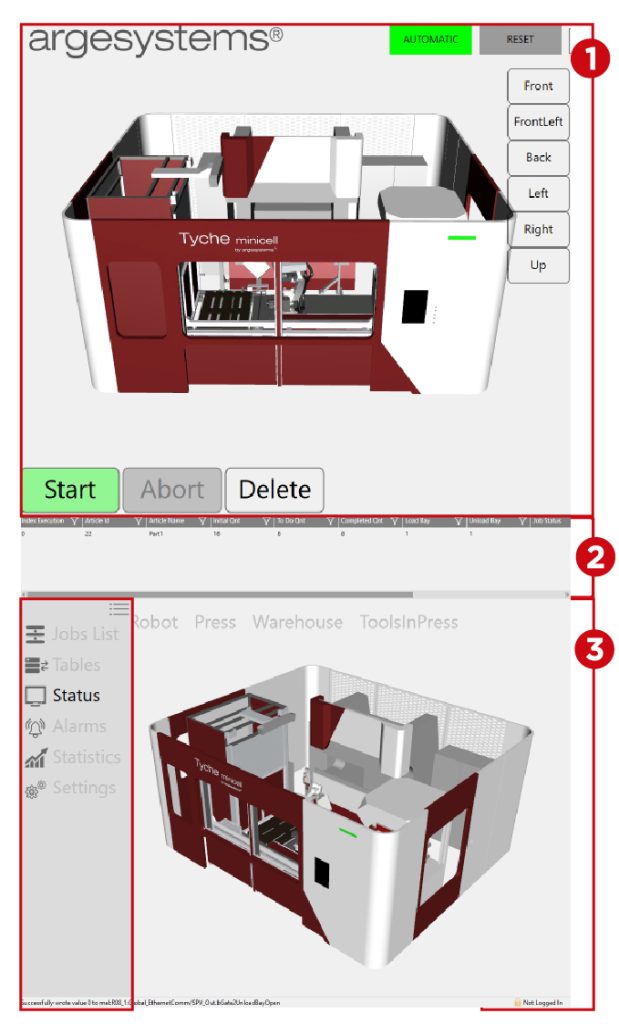

arge.visor interface (fig.1) has been designed to offer maximum ease of use and flexibility. It is displayed on a vertical full-touch monitor, separeted into three sections:

1. Overall monitoring of the bending cell

The first section of the interface provides a overall, real-time view of the cell. All components – including the robot – are displayed in an interactive 3D model, linked to their corresponding sensors.

The display precisely reflects what is happening inside the cell, due to an interactive 3D representation.

Smart maintenance

The virtual dashboard gives acess to the electrical diagrams. A functionality that simplifies the maintenance, minimizes the downtime, and makes instant, intuitive and handy the information.

2. Production status of the bending cell

The second section is dedicated to production management of the cell, focusing on the production list.

arge.visor interface grants users to start the production cycle, monitor order status in real time, and check the operational status of the cell (in production, standby, or alarm). The system also records start and end time of each bending batch.

3. Customizable option menu

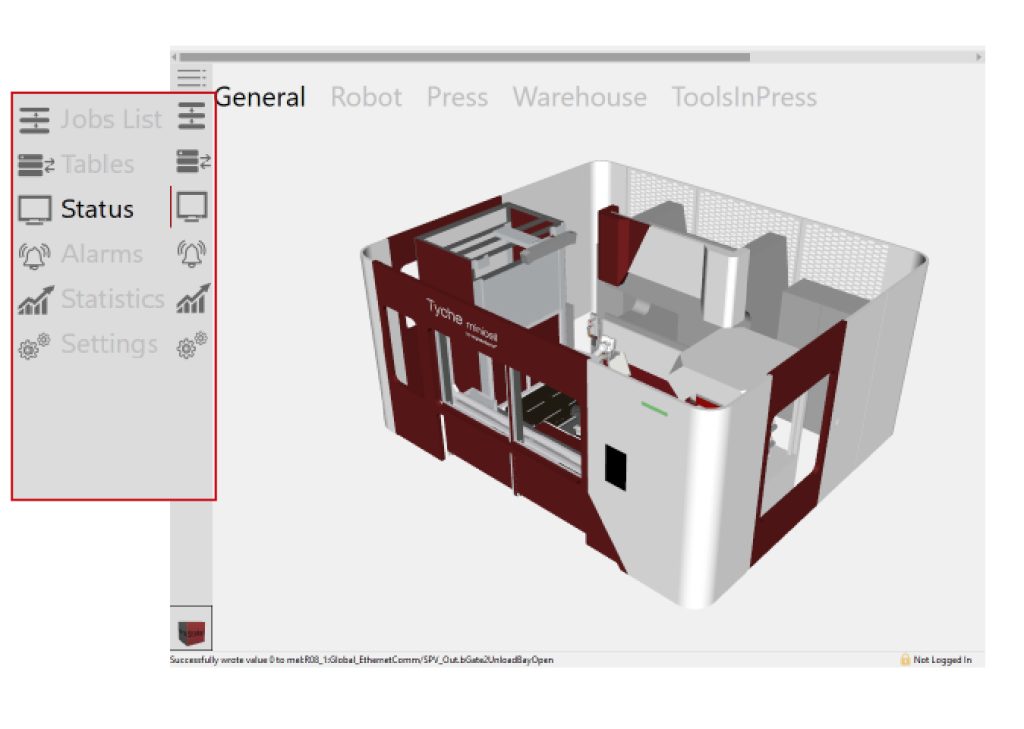

The third section hosts an interactive option menu. Through the drop-down menu (fig.2), the operator accesses quickly different functionalities, such as:

- Job list: displays the production trend in real time, with the possibility to select programs and prioritize job lists.

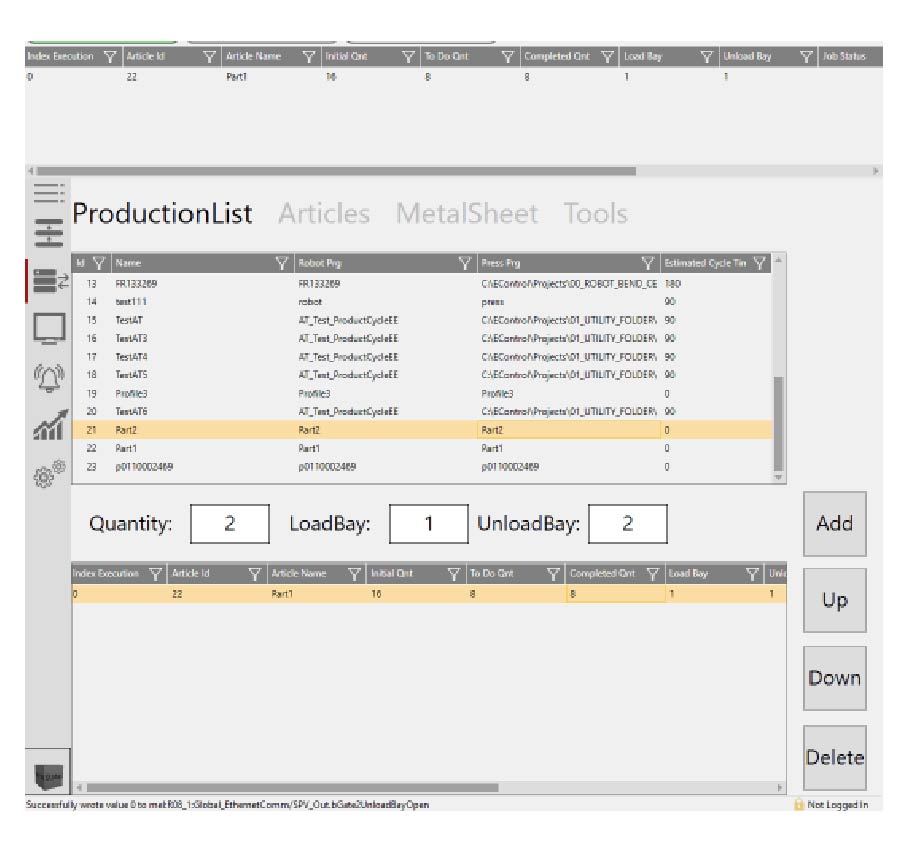

- Tables: enables users to view and configure various operational tables. For example, a Production List can be created to organize the cell’s production.

Focus on “Production List”

The Articles section provides access to a database of pieces, that have been already produced in order to easily repeat past orders.

The Tools table section, users have a complete overview of the tools available in the storage, with their specifications and configurations, enabling setup management.

- Status: Through the 3D interface, the operator controls the bending cell working status in real time. In a bending cell equipped with dual loading and unloading stations, for instance the doors can be easily opened and closed with a simple tap on the screen. This feature allows the operator to safely act during the loading and unloading process, feeding the production assuring non-stop productivity at the same time.

Focus on “Status”

Through the same panel, the operator can quickly access real-time bending cell status, as:

Robot and press brake with indication of their operating status (manual or automatic).

Tool storage: access to available tools and those already set on the press brake.

- Alarms: the software offers advanced control through real-time alarms and error notifications, capturing any issues that arise during the bending process. This feature is specifically designed to prevent production stops and minimize downtime.

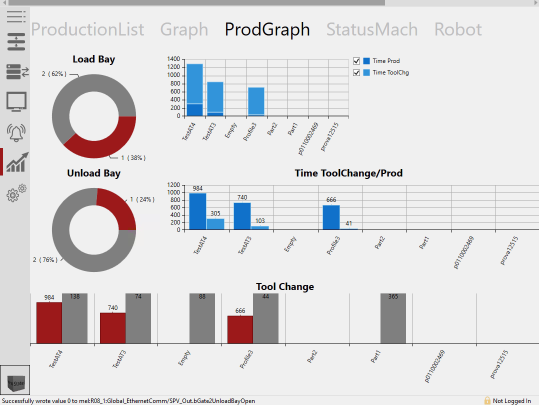

- Bending cell statistics: completely customizable to meet specific client requirements, this section provides a detailed overview of the cell’s performance. It includes:

- Exact number of bended pieces

- Production and setup times

- Average of loading and unloading stations (fig.3)

- Real-time press brake and robot key data, such as axis speed

- Diagnostic section designed to facilitate technical support.

Moreover, a dedicated diagnostics page is also available, designed to simplify technical support and to provide in-depth monitoring of communication variables between the cell, the CNC, and other components.

arge.visor key benefits

arge.visor improves operational efficiency and ensures the continuous operation of the robotic bending cell in a simple, intuitive, and immediate way.

In fact, the whole software is designed to maximize efficiency, safety, and constant production – from real-time supervision to a customized tool management, including performance monitoring and access to historical database.

Do not miss the latest news from argesystems®