Technology at the service of experience

The history of industrial revolutions teaches us that machines have been part of human existence for a long time. At the time, the question was whether industrialization should have been conceived as a threat or a possibility for humanity.

When dealing with automation processes in production, robotics emerges as a crucial element that can improve efficiency, safety and quality. For this reason, Argesystems has in recent years chosen to expand into the field of robotics by adapting this technology to the field of sheet metal bending, where it has been operating for more than 10 years.

Daily fatigue in carpentry doesn’t allow for experimentation and there’s often a certain resistance to technological progress. Despite the value of the robot in production, it should never be considered a substitute for human operators, whose presence remains fundamental. It’s precisely this aspect that we want to focus on: technological solutions should not be seen as a substitute for human capabilities, but as means for enhancing them.

A specialized bender will then have the opportunity to advance in his career by putting his skills at the service of machines and facing with greater agility any problems related to the production of complex parts.

Company advantages in robotic bending

The success of companies investing in robotic bending today lies in their ability to anticipate change and answer to market demands. This choice offers several advantages, including an improvement in system safety: in fact, operators can avoid manual handling of heavy metal sheets, thus reducing risks and physical fatigue.

In addition, automation can provide consistency in terms of quality and availability of workforce. Machines can operate unsupervised during night shifts and therefore prolong working days, while helping to improve production performance without endangering work quality.

Argesystems proposal

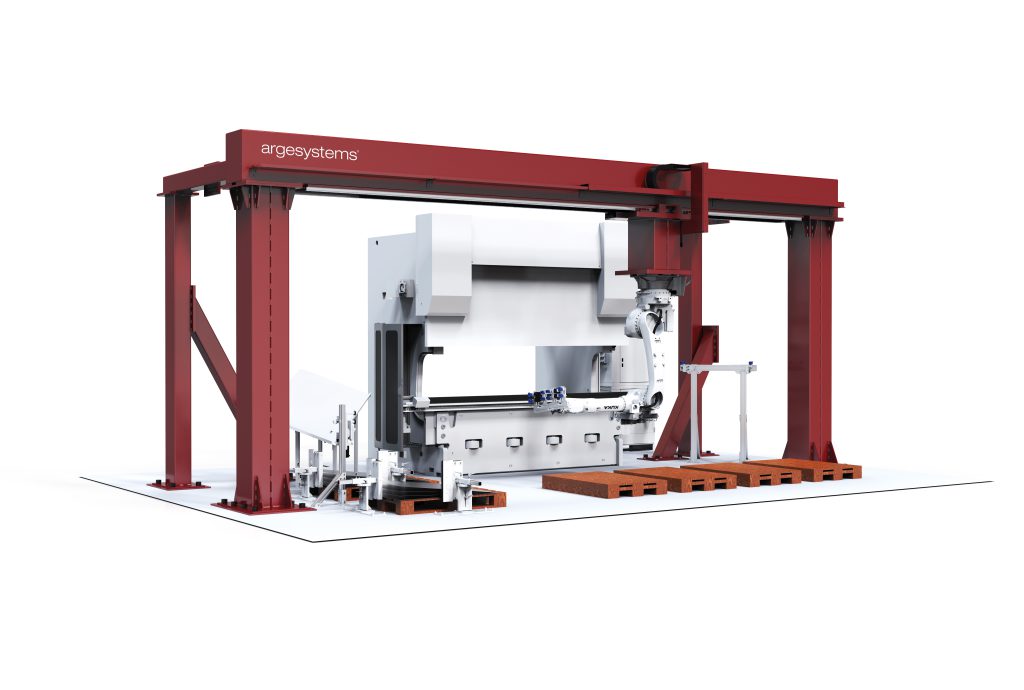

The added value of robotic cells developed and manufactured by Argesystems lies in the use of the eighth axis during the bending phase. This solution improves the palletizing capacity of the components after the bending process. In addition, portal systems open up the possibility of production flexibility, since bending can be done either manually by the operator or automatically by the robot. The solution also leaves space available in front of the press brake allowing the operator to intervene freely once the robot is parked.

Another strong point to keep in mind is that Argesystems uses a particular software to manage its robotic cells, which allows you to program the system offline directly in the technical department. The advantage is that thanks to a single software you can program both the manual and the robotic bending process, since the software automatically provides the configuration of the tools and the bending sequences.

“In Argesystems’ growth path, humanity blends in perfect harmony with technological progress, creating a winning combination that leads the company towards a more promising future. Our path is in continuous evolution, and this is why we invite you to stay updated on our future developments.”